CarBŒN Concept EV

An Open Source Project

Revised 17 September 2010

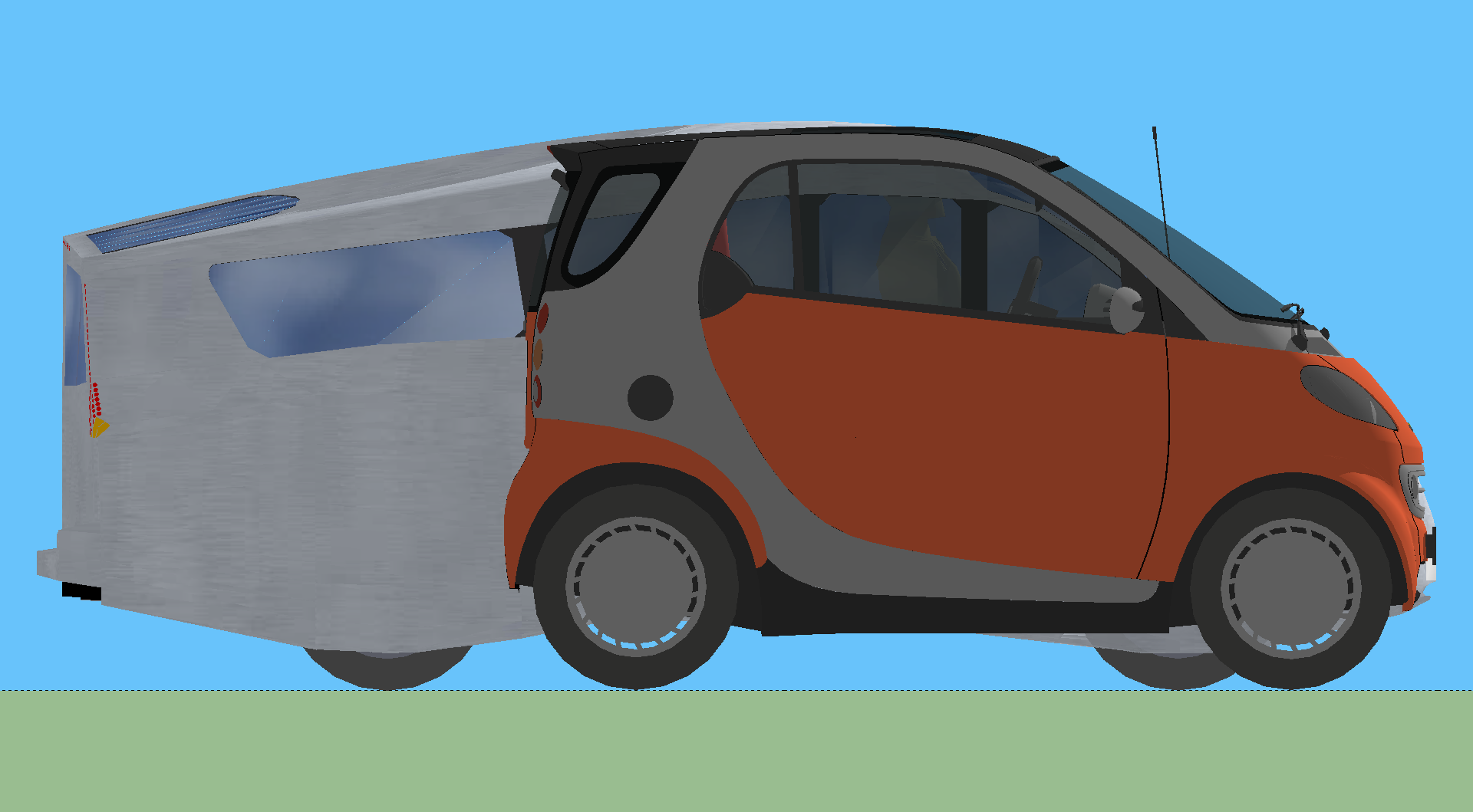

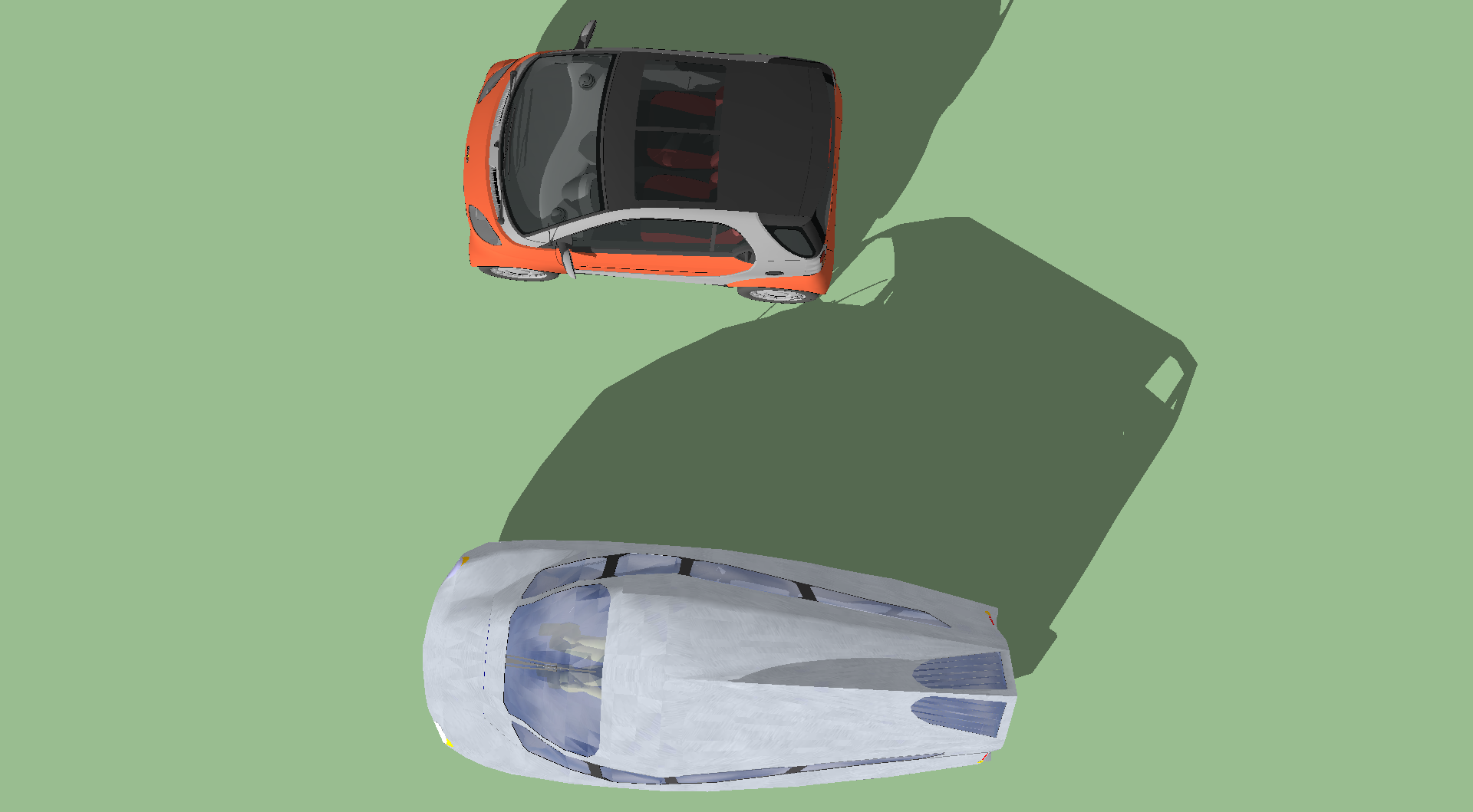

I've been revising the model in SketchUp (and I can email you the file if you want!), and here are some new images:

Slightly older version:

Some images comparing CarBŒN v Smart ForTwo:

Some of these were rendered for me by C. Michael Lewis, from Portland ME. Proving it is a small world, he works both in architecture (and has mutual friends) and he races in the Electrathon series, and he currently holds the speed record of 62 Miles in an hour; while getting 2,249MPGe!

This is the first model, made from basswood:

Project Outline

Design and build an uber-efficient electric car; that has very low aerodynamic drag, as low weight as possible, is designed with good safety and crash protection, is practical to drive (i.e. it is not too big and has nimble handling), and I would like it to carry 4-5 people. By the way, the reason I chose the name

CarBŒN: it is a play on the word carbon (I want to not waste any), and the change in spelling are my initials backwards; combined with the correct spelling... :-)

The basis for the aerodynamics is an early clay model of the Mercedes Bionic car (aka “Boxfish”) that was itself based on the boxfish. The tested coefficient of drag (Cd) of this model was an amazing 0.095 (http://www.ae-plus.com/key%20topics/cc-mercedes-news10.htm) and it seems like a great place to start! The later Bionic car had a Cd of 0.19, which is still very good; but the open wheels and wider shape in the back are the primary reasons for the increase in drag. Another design that inspired a lot of the CarBŒN design is the Schlörwagen – a very aerodynamic design from 1939.

My idea that will allow the wheels to remain covered, and therefore (hopefully) achieve a Cd nearer to the blue model than to the Bionic car, is to have articulated front wheel covers that move with the wheels in sharper turns. I'll get more into the details of how this could work later on.

To achieve low weight, I think the ideal structure would be carbon fiber reinforced plastic. But this is difficult for me to work with, as I have no experience with it, and I think the prospect of making molds and the fumes, etc. is daunting. I've also considered welding a steel tube chassis, and then make either a fiberglass or aluminum body. But I think this would be heavier, and while I have access to a MIG welder; it is not as good as an aluminum monocoque chassis.

I got the idea for how to do this from seeing a friend who is building an airplane from scratch. It is a 2 seat acrobatic capable, and the dry weight (including the 4 cylinder 80HP engine) is between 570 and 620 pounds. I think the process he is using, which plotting out full size templates, and then forming the 6061-T6 sheets into the ribs and the skin; using wooden forms – makes a lot of sense to use this method to build this car.

Aluminum is fully recyclable, it is not dusty, has no fumes, and only requires a small bandsaw, a pair of “pleating” pliers, a soft hammer, and riveting tools. If I start with a 3D CAD model and drawings generated from that, the templates will be accurate. The resulting chassis should be lighter than I could manage with steel, and it forms the body at the same time.

Starting with the Sonex airplane (http://www.sonexaircraft.com/aircraft/sonex.html) and its weight of 620 pounds (~130 pounds for the engine is included in that) – the 22' wingspan and 18' long fuselage have roughly similar surface area to my CarBEN design and so it should weigh about the same (490 pounds). The AC electric motor and mechanical drive train are maybe a little heavier than the plane's engine; say 150 pounds. Add the four wheels, brakes, and the suspension (say 250 pounds) and the battery pack (say 400 – 600 pounds), the seats (which will be quite light – more later) and miscellaneous stuff will add 150 pounds. The the total vehicle weight could be in the 1450-1650 pound range. I would be very happy with anything under 1800 pounds.

The first order of business is to get the overall chassis to be as low drag as possible: I can loft a 3D CAD model from the wooden model I have made, but I think it would be better/faster/cheaper to have the model 3D scanned and use the mesh model for virtual aerodynamic testing. A program that can do 3D flow would be very important to check the form and to adjust it to lower the drag as much as possible without making it impractical to drive. i.e. I'm 6'-4” and I want to fit comfortably, and I need to fit my family, too.

For the safety considerations, the first thing I am doing is making the structure surround the passengers, and in order not to weaken it with doors, like most cars do. Like all design decisions, this involves some compromise, and I have been considering what some other designers have done: both the VW 1L and the FVT eVaro have canopies (like a jet fighter airplane), so that the structure around the passengers is continuous; the compromise comes in inclement weather, as the roof is not over the seats. Another car design that uses an unusual door and entry method is the Loremo; the entire windshield and hood hinge up (from the front) and you step over the side and pull the door back down in place. This also involves the steering wheel and column hinging up and out of the way with the door. The passengers get in through the rear hatch (and they sit facing backwards).

So, the initial door concept I am hoping to use is: in order to maintain a wraparound structure for safety, there is a single door in the rear of the CarBŒN. It has two parts: a sloped hatch that is approximately the back 1/3 of the roof; it lifts up but remains (mostly) covering the opening from precipitation. The rear fascia of the car is a pair of small hinged doors that swing out. This is a a good a place as any to put in the drawing:

|

| CarBŒN Concept EV Mk 2.7 |

(I need to update the drawings to reflect the latest computer model.)

To get in the CarBŒN, people would step up to the floor, and then turn to close the back doors, and the walk up the “aisle” to their seat. (This hopefully explains the staggered seat placement?) The overhead hatch would be closed – the details need to be worked out. If this door idea is not workable, or involves too much effort, then the fallback solution is to have conventional side doors – but I would use 3 or more latches (instead of the usual one) so that the door has 5 (or more) points of attachment (instead of the usual 3) so that the opening is not unduly weakened, and the passengers would be well protected from side impacts.

The other key solution to getting the CarBŒN to work within a very low drag chassis, is the idea of articulated front wheel skirts (see the top, side and bottom views in the drawing). [Edit: I think these would be easier to make, using a vertical hinge down the center (or steering pivot) line, with a front section and rear section. Only the section that is needed to protrude out to allow room for the wheel would be moved. This system would be much simpler than the first idea I came up with, which follows.]: These consist of a ¾ moon panel on the bottom (shown with a dotted line) and another ¾ moon panel on the outside of the front wheel (also shown with a dotted line). There is a slot in the bottom panel where the wheel protrudes out, and there is an inner fender and curved panels that keep the wheel covered even when the steering is all the way to one lock or the other. The suspension motion of the wheel does not move the skirt assembly – the tire moves up and down through the slot and within the inner fender. The whole assembly pivots on grooved rollers around the edge of the bottom panel (see the small circles on the bottom view drawing) and a pivot at the top of the inner fender.

The steering pushrods are connected to the skirt assembly, and swing it with the wheel when the steering angle is sharper than needed for highway driving. So, at high speeds the aerodynamic shape remains unchanged, but at low(er) speeds when sharper steering angles are needed, the panels move to maintain clearance around the wheels. This is the biggest compromise made in the Schlörwagen design – they made the front wide enough to enclose the wheels even when they are at either steering lock. The Schlörwagen is 2.1 meters wide (6'-11”) which has a large affect on the area and hence the drag (CdA) and the car is wide; making it more difficult to drive. It also means there would be more body roll than would otherwise happen.

The battery pack (the 4' x 4' x 6”rectangle) should fit in the floor, between the four wheels. The AC electric drive train is a typical front wheel drive system; which will provide the best ability to have regenerative braking, to regain some of the power. I intend to use a super capacitor in parallel with the battery pack, which allows higher current to be absorbed from regenerative braking to be absorbed, and it can provide bursts of high current for acceleration, greatly reducing the battery load during charging and discharging, while driving. The folks at http://chargecar.org/ (at Carnegie Mellon) are working on enhancing this kind of system with “smart” programing that uses data from your commonly driven routes (using GPS to locate where you are driving) and elevation data to “anticipate” how to best manage the regenerated power, and to make the best use of the supercapacitor; as a power cache.

In order for me to design a simple braking system (without the complexity of an integrated braking system), I would use two brake pedals: the center pedal would be a conventional brake pedal, that operates the hydraulic braking system. This would let the driver's habits be the default in a panic situation. The pedal on the left (about where the clutch would be in a manual shift car) would be the regenerative brake pedal. This would allow for a true coasting mode – both feet off of all pedals, that is easy an predictable. (This is key to good ecodriving; no matter what is powering the car.) Then, if some slowing is needed, the driver can use the regenerative brake as much as possible, and then use the hydraulic brake to supplement the regenerative brakes, if needed.

To save weight and space inside the car, I would make the seats with a mesh fabric stretched over frames; like some office chairs. This sort of seat are now being used in several concept cars, from VW, Toyota, and Honda for example. With the right ergonomics, these would be very comfortable, even for long trips, and they would “breathe”to help keep people cooler in the summer; reducing the need for other cooling methods.

I will try to make an effective passive air circulation system, with the intake(s) located in high velocity areas on the front or sides of the car, and I would provide for passive air extraction out the back of the car; exhausting into the low pressure wake zone at the back of the car. This could actually improve the drag a little; or at least minimize the increase due to the air flowing through the car. This passive air flow could also be tapped to cool the battery pack, and or the electric motor if needed.

The wheels and tires initially would be conventional, but instead of inflating the tires with air, I would use a foam – this would negate the need to keep track of the pressure, and it would probably minimize the rolling resistance, and tire wear would probably improve, because the temperatures would be kept low, since there would be virtually no flexing. The suspension would be designed to do all of the work (air inflated tires absorb a fair bit of the smaller bumps in the road), and it would provide very low rolling resistance. Later, I would install regenerative shock absorbers (apparently, these are currently being developed at Tufts University), and as much of the energy from the motion of the suspension as could be regained would help reduce the losses, by recharging the battery pack a little. (Rather than being wasted as heat in the tires and in conventional hydraulic shock absorbers.)

My intention is to test the aerodynamic drag virtually, using a 3D “solid” model. The computer model could be made from the wooden model, using laser scanning, or it could be made from scratch based on the 2D drawings that I've made based on the wooden model. If there is anybody who is interested in contributing work on this computer model, please contact me.

The standing figure is 5'-9" tall for a visual reference, and these are perspective images, so things closer to you appear larger. The windows and lights are a first pass, so do not read too much into them, though I think that they are schematically close to what is needed.

My next step is to test the 3D model in a CFD (computational fluid dynamics) program to see if it is aerodynamic enough -- hopefully I can then make improvements in it, and start thinking more about the chassis construction.

I made a video animation of the model in SketchUp on YouTube:

I will lay them out in DataCAD to try and fit as many as possible on each sheet. I'd like to be able to test the physical size and layout of the entry method and seat layout etc., before committing to build this car.

Now, I want to have a composite foam sandwich monocoque, both for strength and for thermal insulation, so do I need to form the inner walls on the inside of the formers first, and then do the outer surface, and then foam in between?

How do I best form the surface using the formers?

Do I need to use Styrofoam and carve it, or can I use wires and/or screening as a substrate for the composite?

It is okay to leave the plywood in place and have it as part of the structure, or is is better to pull it out and then rejoin the surfaces with spacers/foam?

Is fiberglass significantly less expensive than carbon fiber, and what are the advantages/issues with each?

I can cut the plywood so that the windows are slightly recessed, to form the lip/flange -- should the windows just be left open and trim the edges, or does it help to cover them over completely and then cut out the openings?

For the main hatch door, and the rear doors, should they be formed as part of the whole outer skin, and then cut out? Or, should the opening be left out of the main piece and then make the doors themselves separately?

I want to form a surrounding "beam" around the front and sides of the passenger compartment (which will double as the main air duct into the passenger compartment) -- I hope to have it flush on the inside, and let it into the formers. If the beam was metal, it could be hollow -- can it be made from composite and be hollow?

I'm trying to figure out how to best do the crumple zone in the front: a tubular subframe or a composite structure? Have you seen "crush cones" used between a structural bumper and the firewall/structural passenger cell?

How does the suspension get attached to the monocoque -- do reinforcing plates need to be embedded, or...?

I'm hoping to hear from FVT about the size of their battery pack, so I can try and lay out how it will fit inside the floor. I would ideally try and at least have the space for a really big battery pack (50-60kWh!!) so I can get 300-400 mile range. This would be incredible if it could be made to fit!

I would love to hear whatever your thoughts are! Thanks in advance.

CarBEN EV5 by Neil Blanchard is licensed under a Creative Commons Attribution-ShareAlike 3.0 Unported License.

I don't think hiding front wheel helps you as much in Cd as complexity of wheel turning structures weight increases rolling resistance.

ReplyDeleteRolling resistance applies to all speeds, straight or turning, while low Cd helps any significant amount only when car is going relatively fast and going fast means that tires are in line with the body. Just cover the tire itself with smooth hubcaps. For small citycar like this low weight is more important than excellent CdA.

Also it looks like you have a tiny S-shaped curve between hood and windshield. Ideal shape for low Cd is a "droplet", which means that front of the car should be single smooth curve.

You might also want to hide those windshield wipers under the hood (all modern cars already do that) and add side mirrors (legislation) into initial design. That way you don't need to retrofit them in already designed framework in which case you might have more difficult time to get them as aerodynamic as possible.

ReplyDeleteLooks like the back of the car where the proposed door would be is only the height of half a man, so I assume getting in and walking along to your seat would be quite awkward. Your rear door idea might be a good one, but why not make a mock up of it from wood or polystyrene or something, just to check its actually practical. I'm imagining people awkwardly crawling along to find their seat.

ReplyDeleteThanks for the comments, Timo and Nick!

ReplyDeleteThe articulated front wheel skirts are hinged from the body, so they won't affect the rolling resistance. Aero drag starts to be significant at ~35-40mph. The mechanism is fairly simple really, using a panel only for the part of the tire that protrudes out, pushing it with a "lazy" connection to the steering linkage.

Check out the new images of the Mercedes Bionic/Boxfish car with the amazing low Cd of 0.095:

http://smg.photobucket.com/albums/v724/NeilBlanchard/CarBEN%20EV%20Concept/

And yes you are right rolling resistance is also critical -- after I build the CarBŒN prototype, I hope to work on rigid, non-inflating tires/wheels for ultra low rolling resistance; and the suspension would need to be retuned. Also, if I could use regenerative shock absorbers, then having rigid tires would transmit much more motion to the suspension, and thereby regenerate more power.

Several X-Prize cars and other low drag cars have the wiper vertically up the windshield. Because of the shape of the windshield, the only way to sweep it well meant the wiper had to be this way.

And on the latest version (Mk 2.6) I have grafted in a actual windshield from the Smart ForTwo, so then the wipers could tuck down.

I plan on using video cameras for mirrors, and if I am forced to use optical mirrors, they would be inboard of the windows and just have the glazing bulge out a bit. I am totally serious about have as low a drag as possible, and I am not going to build a uber-low drag car only to tack mirrors on the outside.

The upper part of the opening comes from the large hatch door that hinges up and it also provides a bit of a roof in inclement weather. You would have to stoop/bend over a little more as you get closer to the front. This is obviously a compromise, to try and maintain lots of strength in a crash and keep the weight down as much as possible -- but if it is not workable, I would add a side door.

Thanks again for your comments -- if you would like to see the SketchUp model for yourself (there is a free version of SU available from Google.com), I'd be happy to email it to you. I am going to be adding some of the features on the early Bionic/Boxfish model in those new pictures.

Sincerely, Neil

Here's my earlier blog post on video mirrors:

ReplyDeletehttp://neilblanchard.blogspot.com/2010/09/eyes-forward-video-mirrors-on-my-xa.html

And a whole list of efficiencies for cars:

http://neilblanchard.blogspot.com/2010/09/more-ways-for-auto-makers-to-build-more.html

Neil

I love knowing that I'll be able to fit in this at 6'3", since you're tall yourself. :-)

ReplyDeleteHi Luke,

ReplyDeleteYes, the front three seats will fit people at least as tall as myself. Please note that with the staggered seating, the legroom is actually very flexible and even more room is available if you put your legs to the side.

Sincerely, Neil

Maybe single backdoor instead of double-door? Rear visibility is important and that bar just middle of the door is a bad thing.

ReplyDeleteAlso in your drawings in top of the page it looks like there is a rather sharp corner from front lights to side-panel. You might need to smoothen that up.

Hi Timo,

ReplyDeleteThat might make sense -- I'll have to wait until I'm actually building it, before I decide. The vertical windows are quite low (see the latest images with the doors open, to get a good idea of their size), and the center mullion may not matter much down there. The long(er)windows in the hatch are much more usable for seeing out the back, and they really need the structural support in the middle, I think.

Sincerely, Neil

Hi great readingg your post

ReplyDelete